- Empty cart.

- Continue Shopping

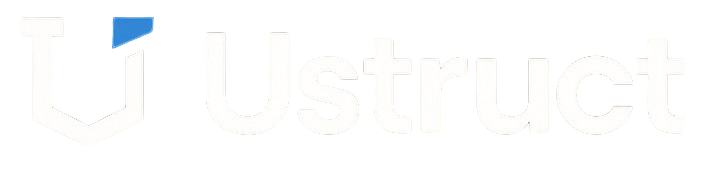

Automatic Dry Chemical Fire Extinguisher Production Line

$212,941.65

99 in stock

Automated Dry Chemical Fire Extinguisher Packaging Solution

This ZONESUN ZS-FE1 production line is engineered to handle the complete packaging process for dry chemical fire extinguishers, offering a turnkey solution for manufacturers. This system was specifically configured for a client in Spain, demonstrating its adaptability to international production standards.

Comprehensive Production Workflow

The line integrates multiple specialized machines to ensure a seamless, high-speed operation. The process flow includes:

- Precise powder feeding and filling

- Automated oil greasing application

- Top placement and secure body turning

- Reliable top sealing mechanism

- Accurate label applying

Key Machine Specifications

This integrated system features robust components designed for efficiency and durability. Note the specifications for the core machinery:

Filling Machine (Model ZS-FM6A)

- Power: Approximately 4KW

- Filling Range: 6-8kg per head (Customizable)

- Filling Heads: 4

- Working Speed: Approximately 500 bottles per hour

Sealing Machine (Model ZS-XG22)

- Power: Approximately 3.5KW

- Capping Heads: 2

- Working Speed: Approximately 500 bottles per hour

Labeling Machine

- Capacity: 15 pieces per minute

- Product and Label Size: Customizable to your specific extinguisher dimensions.

We provide comprehensive solutions tailored to meet your specific production demands, ensuring every extinguisher is packaged professionally and securely. The system also accommodates specific mounting requirements, such as ensuring the handle and wall hook angle is set to 90 degrees.

High-Accuracy PP Woven Bag Packaging Machine

$201,028.27Aluminum AC Hose Barb Connector for HVAC Repair

Price range: $11.15 through $13.40Shipping Details

- Please pay more attention to your order address which MUST MATCH your shipping address. (If you’re from Russia, Please leave your full name. It is very important)

- Items will be shipped within 3 business days after payment.

- Please check items when delivered, if damaged, please kindly accept it and contact us immediately. We will make a confirmation and resend you a new one.

| Shipping By | Shipping Cost | Estimated Delivery Time | Tracking Information |

| Thembay Express | Free Shipping | 12-20 days | Not available |

| LEX | $20.00 - $50.00 | 04-12 days | Available |

| Lorem Ex | $26.00 - $70.00 | 03-17 days | Available |

Packaging Details

- Unit Type: piece

- Package Size: 25cm x 32cm x 5cm (9.84in x 12.60in x 1.97in)

- Package Weight: 0.56kg (1.23lb.)

Reviews

There are no reviews yet.