- Empty cart.

- Continue Shopping

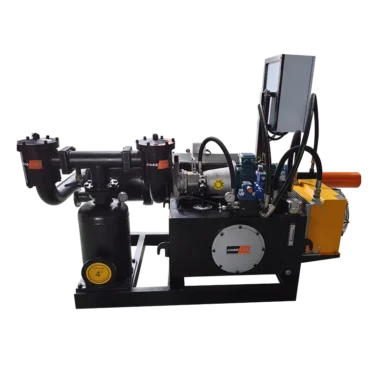

DHM80D CNC Horizontal Milling Center with Fanuc Control

$768,417.39

DHM80D CNC Horizontal Milling Machining Center

The DHM80D is part of GuoSheng’s new high-end product line, engineered for versatility and robust performance. Featuring three-axis heavy roller guides and an integrated high-speed mechanical spindle, this machine excels in demanding manufacturing environments. It seamlessly transitions between high-speed, high-precision work and heavy cutting operations on various materials, including aluminum, steel, and castings.

Key Structural Advantages for Precision and Rigidity

Built for longevity and accuracy, the DHM80D incorporates superior structural design elements:

- Bed and column molding ensures excellent overall rigidity and stable machine accuracy.

- A stable triangular structure combined with double reinforcement plates significantly enhances column rigidity.

- The Z-axis guide rail features a long span, providing exceptionally stable support during deep cuts.

- Standard three-axis screw hollow cooling reduces screw temperature rise by up to 70%, maintaining thermal stability.

Advanced Components for Superior Machining

Performance is driven by high-quality components, ensuring reliable operation and precision:

- Strong Cutting Spindle: The gear spindle head is cast in one piece, offering greater rigidity than combined structures, leading to stronger cutting ability and higher accuracy.

- High Precision Rotary Table: The B-axis rotating worktable is driven by a Japanese imported FANUC AC servo motor and utilizes a hydraulic clamping system for maximum precision and rigidity.

- Reliable Tool Library: Features an automated chain servo tool library using the shortest path fixed address method, simplifying tool management and minimizing collision risks with large tools.

Designed for Efficiency and Maintenance

The DHM80D prioritizes operator efficiency and simplified upkeep:

- Ergonomic Design: Features a widened operator pedal and reduced distance between the workpiece and the operating panel, improving efficiency for operation and clamping, while enhancing operator safety.

- Centralized Maintenance: The lubrication control unit and air pressure unit are centrally located on the operating side, facilitating quick and easy routine inspections.

- Effective Chip Removal: Chips are directed through a center groove directly under the spindle during cutting, preventing accumulation and keeping the processing area clean.

Ideal Applications

This machining center is perfectly suited for precision machining across critical industries, including automotive, aerospace, petroleum, electric power, locomotive manufacturing, plastic machinery, and construction machinery.

Shipping Details

- Please pay more attention to your order address which MUST MATCH your shipping address. (If you’re from Russia, Please leave your full name. It is very important)

- Items will be shipped within 3 business days after payment.

- Please check items when delivered, if damaged, please kindly accept it and contact us immediately. We will make a confirmation and resend you a new one.

| Shipping By | Shipping Cost | Estimated Delivery Time | Tracking Information |

| Thembay Express | Free Shipping | 12-20 days | Not available |

| LEX | $20.00 - $50.00 | 04-12 days | Available |

| Lorem Ex | $26.00 - $70.00 | 03-17 days | Available |

Packaging Details

- Unit Type: piece

- Package Size: 25cm x 32cm x 5cm (9.84in x 12.60in x 1.97in)

- Package Weight: 0.56kg (1.23lb.)

Reviews

There are no reviews yet.