- Empty cart.

- Continue Shopping

Automatic Rebar Cold Rolling Mill Machine Line for Ribbed Steel Bar

$401,960.47

Add to cartAutomatic Rebar Cold Rolling Mill Machine Line for Ribbed Steel Bar

$401,960.47

10 in stock

-

Size Guide

Size Guide

SIZE CHEST WAIST HIPS XS 34 28 34 S 36 30 36 M 38 32 38 L 40 34 40 XL 42 36 42 2XL 44 38 44 - Delivery Return

- Ask a Question

Guaranteed Safe Checkout

Free

Worldwide Shopping

100%

Guaranteed Satisfaction

30 Day

Guaranteed Money Back

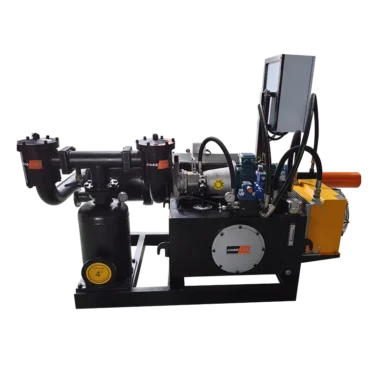

High-Performance Automatic Rebar Cold Rolling Mill Line

This complete production line is engineered for the precise cold rolling of ribbed steel bars, essential for construction, bridge decks, tunnel linings, and various structural applications. Utilizing advanced technology and PLC control, this system ensures consistent output quality and operational efficiency, adhering strictly to European standards.

Key System Components

The integrated line comprises several specialized machines working in sequence to transform wire rod into finished ribbed rebar:

- Derusting Machine: Close-type design with adjustable rotary wheels for easy raw material installation and effective surface cleaning.

- Rolling Mill: Features multiple rolling stands (180mm or 150mm, unique in China) designed with 120° roller angles to reduce diameter and form the required rebar ribs. Rolls are available in alloy tungsten carbide or Chromium 12.

- Plate Machine: Powered by an electromagnetic motor with adjustable speed control to manage the overall rolling speed.

- Stress-Relieving Machine: Essential for reducing material hardness post-rolling.

- Wire Drawing Machine: Equipped with a moment-type motor and specialized wire wheels.

- Straightening and Cutter: Includes pre-straightening capabilities and precise cutting mechanisms.

Advanced Features and Specifications

This CNC intelligent culvert special cold-rolled ribbed steel unit is optimized for producing 3mm to 12mm cold-rolled ribbed steel bars, making it ideal for pipe/culvert manufacturers and small to medium processing plants. The system boasts a high speed of up to 3.3m/s and digital speed adjustment.

| Parameter | Value |

| Control System | Intelligent (PLC) |

| Max Raw Wire Rod Diameter | 5.5-14mm |

| Output Wire Diameter | 3.5-11mm / 3-11mm / 4-13mm |

| Total Power | 220kw – 600kw |

| Layout Length | Approximately 30 meters |

Operational Excellence and Support

We prioritize reliability through rigorous maintenance protocols, including daily checks on electrical systems, oil levels, and component fastening. Our commitment extends beyond delivery; we offer comprehensive support, including installation guidance and worker training by experienced engineers, ensuring rapid and efficient operation.

Contact Manager Violet Ms via WhatsApp (+86 18966023528) or Email (qianruitrading@gmail.com) before ordering to confirm the final price, including transportation and shipping details.

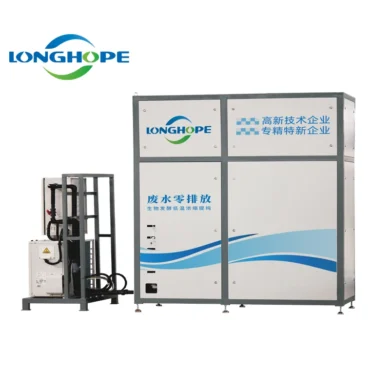

Transparent PTFE FEP Tubing – High Temp, Chemical Resistant Hose

Shipping Details

- Please pay more attention to your order address which MUST MATCH your shipping address. (If you’re from Russia, Please leave your full name. It is very important)

- Items will be shipped within 3 business days after payment.

- Please check items when delivered, if damaged, please kindly accept it and contact us immediately. We will make a confirmation and resend you a new one.

| Shipping By | Shipping Cost | Estimated Delivery Time | Tracking Information |

| Thembay Express | Free Shipping | 12-20 days | Not available |

| LEX | $20.00 - $50.00 | 04-12 days | Available |

| Lorem Ex | $26.00 - $70.00 | 03-17 days | Available |

Packaging Details

- Unit Type: piece

- Package Size: 25cm x 32cm x 5cm (9.84in x 12.60in x 1.97in)

- Package Weight: 0.56kg (1.23lb.)

Related products

9-11pc Hex Socket Nut Driver Bit Set 5mm-13mm Carbon Steel

Precision Diagonal Cutting Pliers – Carbon Steel Flush Snips

Reviews

There are no reviews yet.