- Empty cart.

- Continue Shopping

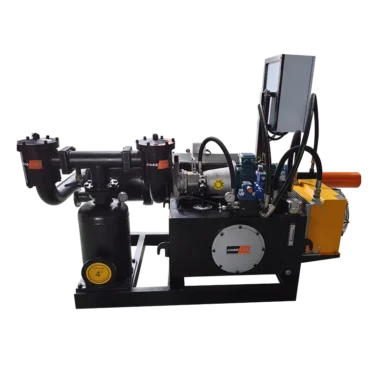

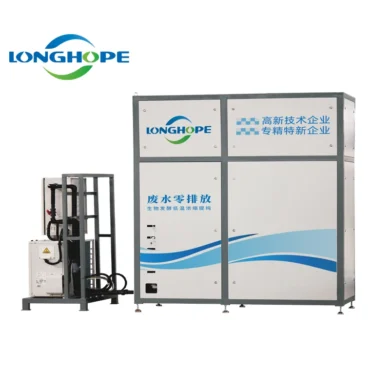

5kg Lab Granulating & Drying Line for Solid Preparation

$279,360.47

100 in stock

Complete Laboratory Solid Preparation System

This comprehensive 5kg laboratory line integrates essential equipment for pharmaceutical and chemical solid preparation, including a high shear granulator, wet granulator (conical mill), and fluid bed dryer. The entire process operates within a closed linkage system, minimizing cross-contamination and meeting stringent GMP requirements for trial production and small-scale manufacturing.

High-Efficiency Granulation Process

The process begins with the GHL-15 mixing and granulating unit, which uniformly blends dry powders before adding binders to create damp material. This wet material is then immediately sized using the wet granulator (conical mill). The system is designed for smooth, compatible operation between all components, ensuring consistent particle size distribution.

Sealed Drying for Product Integrity

Wet granules are transferred via pneumatic vacuum feed into the FL-20 fluid bed dryer. This unit performs simultaneous spraying, mixing, granulation, and drying, significantly reducing overall processing time. It utilizes special anti-static filter bags and operates under negative pressure, ensuring a sealed system that prevents leakage and dust emission while maintaining high repeatability of drying parameters.

Key Equipment Specifications (GHL-15 Mixer/Granulator)

- Tank Volume: 10 Liters

- Load Capacity: 5-8 kg/batch

- Stir Speed Control: 30-960 RPM (Inverter Control)

- Chopper Speed Control: 50-2990 RPM (Inverter Control)

- Operation: Electrical control with optional PLC touchscreen interface.

Fluid Bed Dryer Features

This dryer module is engineered for superior material handling, capable of performing both heavy-weight and light-weight granulation. It features no dead corners for easy cleaning, fast unloading, and stable process parameters, ensuring product moisture content can be controlled between 5‰ and 5% relative to humidity.

Shipping Details

- Please pay more attention to your order address which MUST MATCH your shipping address. (If you’re from Russia, Please leave your full name. It is very important)

- Items will be shipped within 3 business days after payment.

- Please check items when delivered, if damaged, please kindly accept it and contact us immediately. We will make a confirmation and resend you a new one.

| Shipping By | Shipping Cost | Estimated Delivery Time | Tracking Information |

| Thembay Express | Free Shipping | 12-20 days | Not available |

| LEX | $20.00 - $50.00 | 04-12 days | Available |

| Lorem Ex | $26.00 - $70.00 | 03-17 days | Available |

Packaging Details

- Unit Type: piece

- Package Size: 25cm x 32cm x 5cm (9.84in x 12.60in x 1.97in)

- Package Weight: 0.56kg (1.23lb.)

Reviews

There are no reviews yet.